There May Be Too Much Agave in Your Tequila or Mezcal

When you spend your hard earned money on a “good” tequila, you want to know that the producer made the very best tequila they could. Well, for a lot of products that are out there these days, you are not getting the best that they can make. And no, I’m not talking about the distilleries sharing their “family reserves” with us.

(As a side note, this article will make a a lot more sense if you have a good understanding of traditional production methods. If you don't, you can check out my Production page.)

Like wine, the extraction of juice from the agave for tequila is similar in concept to the pressing of grapes. The juices of the first and second pressing are of a higher quality and are used for boutique wines. While juices for the third pressing are added and used for the better, more commonly found wines at your local wine shops and restaurants. The forth pressings are commonly sold of to other winemakers so they can make their “Two Buck Chuck” style wines. As the grape has more pressings, the juice looses it quality and becomes bitter.

After using the tahona (a large stone wheel weighing three tons that is used to press about 70% of the sugars from agave) for over a hundred years, tequila producers started using mechanical crushers or shredders (big steel roller mills with interlocking “soft blades”) to help separate the sweet juice and fibers of the cooked agave. By placing the agave thru the machines multiple times, they are able to extract more juice - up to 85% of the sugars from the agave. For many years, producers would only put the agave thru 2 or 3 times. During times of agave shortages, producers have developed ways to be more “efficient” with the use of the agave – to get the most sugars out of the agave as possible. During the agave shortage of the late 1970’s, they started using a fourth “step” in the extraction process, then at some point in the late 80’s, a fifth step was added. In the late 1990's a major crisis was going on with the agave, and it was scarce. The tequila industry was booming like it never had before, and there was not enough agave to go around. The industry had to make a move to save its self, and the major players, Cuervo Sauza, Herradura, and Cazadores, all bought into difusor technology.

Like the grape, when the agave goes thru multiple stages of crushing it too loses its quality. But unlike wine makers, most tequila producers don’t separate the different pressings. They use all of them to produce their high-end brand, as well as their bargain bin 100% agave tequilas. Then on top of that, some producers use a process called a difusor to extract the last sugars from the already very dry agave fibers.

There are 2 styles of difusors (diffuser would be the English spelling) used in tequila and mezcal production. The first being, the one that is used after the agave has been cooked in hornos or autoclaves, then shredded. The last bits of the crushed fibre is run through the difusor to extract the remaining sugars.

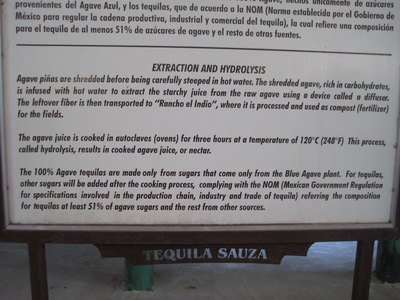

The second use of a difusor is done without cooking the agave at all. Raw agave that has not been cut, or had the cogollo removed (the part of the agave that creates a bitter flavor) is loaded into a shredder. The agave pieces are then placed on a conveyor belt so that hot water to extract 99% of the starches of the agave. Sauza uses this type of difusor for 100% of their products - and it is a pretty big piece of equipment. After the agave enters the shredder, it takes about 4 hours to extract the starches. After extraction, the juice is then cooked in autoclaves for 3 hours at a temperature of 120˚C (248˚ F) to convert the starches to sugar. *As a side note and a correction to my original article, sulphuric acids are only used if a difusor facility does not use autoclaves for hydrolysis. All of the facilities that I have visited or seen pictures of, do in fact, have an autoclave to convert the starches to sugar. If sulphuric acids were being used, there would be lines labeled as such running to the difusors. I have looked for, and have never seen such lines since I have learned about this * At this point, the "wash" is ready for fermentation. I have had a chance to taste the extracted sugars of the agave from this type of difusor, and it tastes like a very bitter agave nectar, with hardly any sweetness. An important element in developing the flavor of an agave distillate, is the cooking of the agave. Earth, brick, and stainless steels ovens each produce sweet tasting agave with distinctive notes in the final distillate. There are no sweet notes what-so-ever, in this difused agave juice, nor was it enjoyable on the palate. There is nothing about the "aguamiel" as Sauza calls it, that can lead to a tasty product. Not only does the difusor take away the flavor of the agave, but also the heart and soul. Factor in a rushed fermentation process of 8 to 24 hours, and another 8 hours for distillation, a disfused product can go from harvested agave to a finished distillate in 24 hours. I guess if the goal is to make a "clean" tasting spirit such as AgaVodka and Mexican Whiskey that doesn't taste like tequila, why use a crop that is so expensive and has heart and soul? Just use corn or wheat - its a lot cheaper and will save you $$$$$$$$$$$$!!!!! While being “efficient” and using 99% of the sugars in the agave, the difusor produces, what I would consider to have a chemical/medicinal taste--sometimes slight, sometimes overbearing flavor profile that always seems to overshadow the beauty of the agave. So if you come across a tequila or mezcal made with a difusor, the only way that there can be "notes of cooked agave" is by adding that flavor during the finishing process. They can add "notes of cooked agave?" Why, yes. Yes they can...I've seen and smelled the additive. It does exist.

(As a side note, this article will make a a lot more sense if you have a good understanding of traditional production methods. If you don't, you can check out my Production page.)

Like wine, the extraction of juice from the agave for tequila is similar in concept to the pressing of grapes. The juices of the first and second pressing are of a higher quality and are used for boutique wines. While juices for the third pressing are added and used for the better, more commonly found wines at your local wine shops and restaurants. The forth pressings are commonly sold of to other winemakers so they can make their “Two Buck Chuck” style wines. As the grape has more pressings, the juice looses it quality and becomes bitter.

After using the tahona (a large stone wheel weighing three tons that is used to press about 70% of the sugars from agave) for over a hundred years, tequila producers started using mechanical crushers or shredders (big steel roller mills with interlocking “soft blades”) to help separate the sweet juice and fibers of the cooked agave. By placing the agave thru the machines multiple times, they are able to extract more juice - up to 85% of the sugars from the agave. For many years, producers would only put the agave thru 2 or 3 times. During times of agave shortages, producers have developed ways to be more “efficient” with the use of the agave – to get the most sugars out of the agave as possible. During the agave shortage of the late 1970’s, they started using a fourth “step” in the extraction process, then at some point in the late 80’s, a fifth step was added. In the late 1990's a major crisis was going on with the agave, and it was scarce. The tequila industry was booming like it never had before, and there was not enough agave to go around. The industry had to make a move to save its self, and the major players, Cuervo Sauza, Herradura, and Cazadores, all bought into difusor technology.

Like the grape, when the agave goes thru multiple stages of crushing it too loses its quality. But unlike wine makers, most tequila producers don’t separate the different pressings. They use all of them to produce their high-end brand, as well as their bargain bin 100% agave tequilas. Then on top of that, some producers use a process called a difusor to extract the last sugars from the already very dry agave fibers.

There are 2 styles of difusors (diffuser would be the English spelling) used in tequila and mezcal production. The first being, the one that is used after the agave has been cooked in hornos or autoclaves, then shredded. The last bits of the crushed fibre is run through the difusor to extract the remaining sugars.

The second use of a difusor is done without cooking the agave at all. Raw agave that has not been cut, or had the cogollo removed (the part of the agave that creates a bitter flavor) is loaded into a shredder. The agave pieces are then placed on a conveyor belt so that hot water to extract 99% of the starches of the agave. Sauza uses this type of difusor for 100% of their products - and it is a pretty big piece of equipment. After the agave enters the shredder, it takes about 4 hours to extract the starches. After extraction, the juice is then cooked in autoclaves for 3 hours at a temperature of 120˚C (248˚ F) to convert the starches to sugar. *As a side note and a correction to my original article, sulphuric acids are only used if a difusor facility does not use autoclaves for hydrolysis. All of the facilities that I have visited or seen pictures of, do in fact, have an autoclave to convert the starches to sugar. If sulphuric acids were being used, there would be lines labeled as such running to the difusors. I have looked for, and have never seen such lines since I have learned about this * At this point, the "wash" is ready for fermentation. I have had a chance to taste the extracted sugars of the agave from this type of difusor, and it tastes like a very bitter agave nectar, with hardly any sweetness. An important element in developing the flavor of an agave distillate, is the cooking of the agave. Earth, brick, and stainless steels ovens each produce sweet tasting agave with distinctive notes in the final distillate. There are no sweet notes what-so-ever, in this difused agave juice, nor was it enjoyable on the palate. There is nothing about the "aguamiel" as Sauza calls it, that can lead to a tasty product. Not only does the difusor take away the flavor of the agave, but also the heart and soul. Factor in a rushed fermentation process of 8 to 24 hours, and another 8 hours for distillation, a disfused product can go from harvested agave to a finished distillate in 24 hours. I guess if the goal is to make a "clean" tasting spirit such as AgaVodka and Mexican Whiskey that doesn't taste like tequila, why use a crop that is so expensive and has heart and soul? Just use corn or wheat - its a lot cheaper and will save you $$$$$$$$$$$$!!!!! While being “efficient” and using 99% of the sugars in the agave, the difusor produces, what I would consider to have a chemical/medicinal taste--sometimes slight, sometimes overbearing flavor profile that always seems to overshadow the beauty of the agave. So if you come across a tequila or mezcal made with a difusor, the only way that there can be "notes of cooked agave" is by adding that flavor during the finishing process. They can add "notes of cooked agave?" Why, yes. Yes they can...I've seen and smelled the additive. It does exist.

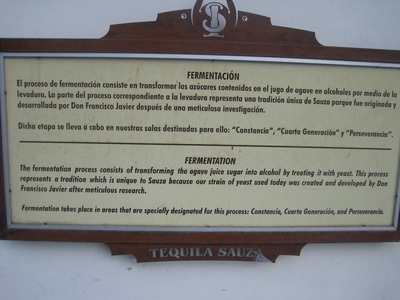

The aguamiel is then pumped to the fermentation area where yeasts, accelerants, and closed top tanks are used to ferment in 8 - 24 hours (it takes 16 hours at Sauza). Distillation is next. While pot stills may be used, theres a good chance that a column still is implemented as well. For those that aren't aware, a column still allows for continuos distillation up to 95% alcohol and strips away any impurities and flavor from the spirit. Sauza uses a combination of column and pot stills very much in the same manner as bourbon - the musto muerto (dead must) runs through the column still to 45% alcohol, then the second pass goes through stainless steel pot still resulting in a distillate that is around 75% alcohol, and tastes very much like vodka and not much like tequila. Hence the term "AgaVodka". Unlike a traditional tequila distillery that takes 7 - 10 days to make their product, a "modern" distillery that uses difusor technology takes 24-36 hours to go from from harvested agave to distilled spirit.

Oh, and did you know? Production of a lot of the commercialized agave nectar starts off this same way. So after tasting how bitter the product is from the difusor, I would guess to say, that it takes a lot of hard work (and maybe a little something extra) to make agave nectar as sweet as it is.

(Click this link for a diagram of agave nectar production with the difusor http://theioaa.com/wp-content/uploads/2011/02/IOAA-Processing-834x1024.jpg)

I also found out that there are producers out there who are claiming to be "Certified Organic". Well, according to the CCOF (California Certified Organic Farmer), "Sulfuric acid when used as an processing aid or ingredient cannot be certified organic." So while the agave might be organic, your agave nectar is not organic, and tequila producers using difusors and claiming to be organic are full of manure! Check the post from July 16 2012 at https://www.facebook.com/CCOForganic. ***I have recently learned that "organic" only applies to the agave, not the production process...

Not only is the difusor a way to pump out product, it also uses a very small labor force. As more distilleries use the difusor, there will be less jobs available to those, who for hundreds of years, have built towns and created families by working in the agave distillate industry. So what happens to the unemployed? Well, Juan Beckman, current owner (as of Sept 4 2012) of Jose Cuervo sees everyone in El Valle de Tequila as having a job in tourism. That's nice and all, but really, El Valle is only a small part of the tequila (and mezcal) industry. Since the Mexican government doesn't seem to be in any hurry to create jobs for its citizens, do they leave for the US to become illegal immigrants? Or do they work for the narcos?

I understand the need for efficiency. So, go ahead and use the difusor for mixtos (which is really is not tequila BTW) and pre-made tequila cocktails. In the end, this is really a plea to the producers to remove your difusors all together. And I really hope that Suntory reads this article and understands that their Sauza tequilas wqould be so much better if they went back to using autoclaves and hornos to produce their puro products so they can once again impart the heart and soul of the agave - of Mayahuel - and return to making good tequila again.

When I put down my hard earned money on a bottle, I want to know that the producer took the time to make it right. As Carlos Camarena, Master Distiller for El Tesoro & Tapatio says “We’ve waited 8 years for the agave to be ready for harvest, I think we can wait a few more days and not rush the process." Thankfully, we still have producers of agave distillates who value the traditions of their fathers, and their father's fathers.

Producers and NOM's of those who use difusors, and brands that are made at that distillery;

- Tequila Sauza (NOM 1102); Tres Generationes, 901, Hornitos, Conmemorativo, Blue/Azul, 100 Años, Hacienda, Sauza

- Casa Cuervo (NOM 1122); http://www.vincentcorp.com/content/tequila Cuervo also uses traditional brick ovens and shredders for some of the products it makes; Jose Cuervo, Gran Centenario, 1800, Traditional, Doble Diamante, Reserva de Familia, etc...

- Destileria Leyros (NOM 1489); Casa Dragones, Don Fermin, Republic, Leyros, Los Azules, Mariangel, Opalo Azul

Check out this video from the distillery http://www.leyrostequila.com/itour.html

- Compañia Destiladora de Xamay (NOM 1534); Capas, Diosa, El Don de la Familia, II 55, Inolvidable Infante, Mi Rancho, Tres Siete

- Productos Finos (NOM 1416) While they do have hornos and autoclaves and "say that they only use their difusor for mixto" at this distillery, it is possible that difused product is used in any of their puro products, including the following and any of the other other 30+ plus brands that are registered to this distillery; Avaion, Casamigos, Clase Azul, JLP, Campo Azul, Rancho Alegre.

- Tequilaria Don Roberto (NOM 1437); Don Roberto, 88 Eighty Eight, Huizache, Tanteo, Señor Frog's, plus 7 other brands.

- Casa Armando Guillermo Prieto (NOM O50X); Zignum

- Brown Forman Tequila Mexico (NOM 1119); post cooking and shredding difusor; Herradura, El Jimador, Don Eduardo, Antiguo, Hacienda de Cristeros. I will have an article about the use of this post-cooking difusor at Herradura soon, but I believe the following information is correct. Herradura used musto that was fermented with sugars from their post-cooking difusor only from 2001 - 2010. The El Jimador line is produced exclusively with sugars from the post-cooking difusor, while Antiguo is a blend of difusor and difusor-free musto. Don Eduardo and Hacienda de Cristeros claim not to be make with sugars derived from the post-cooking difusor. Though, I'm not so sure that Hacienda de Cristeros is even being produced anymore.

*In 2015, I had the opportunity to visit Herradura once again. While my visit was very short, I had the chance to see their entire massive difusor facility. I no longer believe that this distillery is only using cooked agave, but raw agave as well. Our tour guide did tell us about it "that is a different process. We use that only for Pepe Lopez (their mixto tequila) and, Don Eduardo" WOW!! Ok, so a bit different story that what was told in 2014. Also, I have recently tasted El Jimador, and I believe in 100% certainty, that it is now a 100% difused product.

- Bacardi y Compañia (NOM 1487); post cooking and shredding difusor; Cazadores, Corzo, 4 Vientos, Camino Real

- Tequilera 8 Mesas (NOM 1587); This is a new distillery that was built in Tamaulipas and currently only produces Tequila 8 Mesas. This is an interesting video from 8 Mesas that shows how fine the agave gets shredded before it is run through the difusor.

(Click this link for a diagram of agave nectar production with the difusor http://theioaa.com/wp-content/uploads/2011/02/IOAA-Processing-834x1024.jpg)

I also found out that there are producers out there who are claiming to be "Certified Organic". Well, according to the CCOF (California Certified Organic Farmer), "Sulfuric acid when used as an processing aid or ingredient cannot be certified organic." So while the agave might be organic, your agave nectar is not organic, and tequila producers using difusors and claiming to be organic are full of manure! Check the post from July 16 2012 at https://www.facebook.com/CCOForganic. ***I have recently learned that "organic" only applies to the agave, not the production process...

Not only is the difusor a way to pump out product, it also uses a very small labor force. As more distilleries use the difusor, there will be less jobs available to those, who for hundreds of years, have built towns and created families by working in the agave distillate industry. So what happens to the unemployed? Well, Juan Beckman, current owner (as of Sept 4 2012) of Jose Cuervo sees everyone in El Valle de Tequila as having a job in tourism. That's nice and all, but really, El Valle is only a small part of the tequila (and mezcal) industry. Since the Mexican government doesn't seem to be in any hurry to create jobs for its citizens, do they leave for the US to become illegal immigrants? Or do they work for the narcos?

I understand the need for efficiency. So, go ahead and use the difusor for mixtos (which is really is not tequila BTW) and pre-made tequila cocktails. In the end, this is really a plea to the producers to remove your difusors all together. And I really hope that Suntory reads this article and understands that their Sauza tequilas wqould be so much better if they went back to using autoclaves and hornos to produce their puro products so they can once again impart the heart and soul of the agave - of Mayahuel - and return to making good tequila again.

When I put down my hard earned money on a bottle, I want to know that the producer took the time to make it right. As Carlos Camarena, Master Distiller for El Tesoro & Tapatio says “We’ve waited 8 years for the agave to be ready for harvest, I think we can wait a few more days and not rush the process." Thankfully, we still have producers of agave distillates who value the traditions of their fathers, and their father's fathers.

Producers and NOM's of those who use difusors, and brands that are made at that distillery;

- Tequila Sauza (NOM 1102); Tres Generationes, 901, Hornitos, Conmemorativo, Blue/Azul, 100 Años, Hacienda, Sauza

- Casa Cuervo (NOM 1122); http://www.vincentcorp.com/content/tequila Cuervo also uses traditional brick ovens and shredders for some of the products it makes; Jose Cuervo, Gran Centenario, 1800, Traditional, Doble Diamante, Reserva de Familia, etc...

- Destileria Leyros (NOM 1489); Casa Dragones, Don Fermin, Republic, Leyros, Los Azules, Mariangel, Opalo Azul

Check out this video from the distillery http://www.leyrostequila.com/itour.html

- Compañia Destiladora de Xamay (NOM 1534); Capas, Diosa, El Don de la Familia, II 55, Inolvidable Infante, Mi Rancho, Tres Siete

- Productos Finos (NOM 1416) While they do have hornos and autoclaves and "say that they only use their difusor for mixto" at this distillery, it is possible that difused product is used in any of their puro products, including the following and any of the other other 30+ plus brands that are registered to this distillery; Avaion, Casamigos, Clase Azul, JLP, Campo Azul, Rancho Alegre.

- Tequilaria Don Roberto (NOM 1437); Don Roberto, 88 Eighty Eight, Huizache, Tanteo, Señor Frog's, plus 7 other brands.

- Casa Armando Guillermo Prieto (NOM O50X); Zignum

- Brown Forman Tequila Mexico (NOM 1119); post cooking and shredding difusor; Herradura, El Jimador, Don Eduardo, Antiguo, Hacienda de Cristeros. I will have an article about the use of this post-cooking difusor at Herradura soon, but I believe the following information is correct. Herradura used musto that was fermented with sugars from their post-cooking difusor only from 2001 - 2010. The El Jimador line is produced exclusively with sugars from the post-cooking difusor, while Antiguo is a blend of difusor and difusor-free musto. Don Eduardo and Hacienda de Cristeros claim not to be make with sugars derived from the post-cooking difusor. Though, I'm not so sure that Hacienda de Cristeros is even being produced anymore.

*In 2015, I had the opportunity to visit Herradura once again. While my visit was very short, I had the chance to see their entire massive difusor facility. I no longer believe that this distillery is only using cooked agave, but raw agave as well. Our tour guide did tell us about it "that is a different process. We use that only for Pepe Lopez (their mixto tequila) and, Don Eduardo" WOW!! Ok, so a bit different story that what was told in 2014. Also, I have recently tasted El Jimador, and I believe in 100% certainty, that it is now a 100% difused product.

- Bacardi y Compañia (NOM 1487); post cooking and shredding difusor; Cazadores, Corzo, 4 Vientos, Camino Real

- Tequilera 8 Mesas (NOM 1587); This is a new distillery that was built in Tamaulipas and currently only produces Tequila 8 Mesas. This is an interesting video from 8 Mesas that shows how fine the agave gets shredded before it is run through the difusor.